3D for Manufacturing

How Zuant can Transform Manufacturing?

Measure Manufacturing Key Performance Indicators with the Matterport 3D Scanner which allows you to capture key components of your plant’s design. This gives you the ability to reduce management costs and focus on incremental changes to improve operations.

Creating a Matterport 3D Scan of your plant provides you with an immersive cloud-based photorealistic and dimensionally accurate digital twin, enabling you to increase productivity, collaborate more smoothly with relevant stakeholders and make use of enterprise manufacturing intelligence (EMI).

Be a part of industrial transformation by taking a data-driven approach to operations giving you real-time KPIs in a dashboard that enables you to improve quality, flexibility and efficiency.

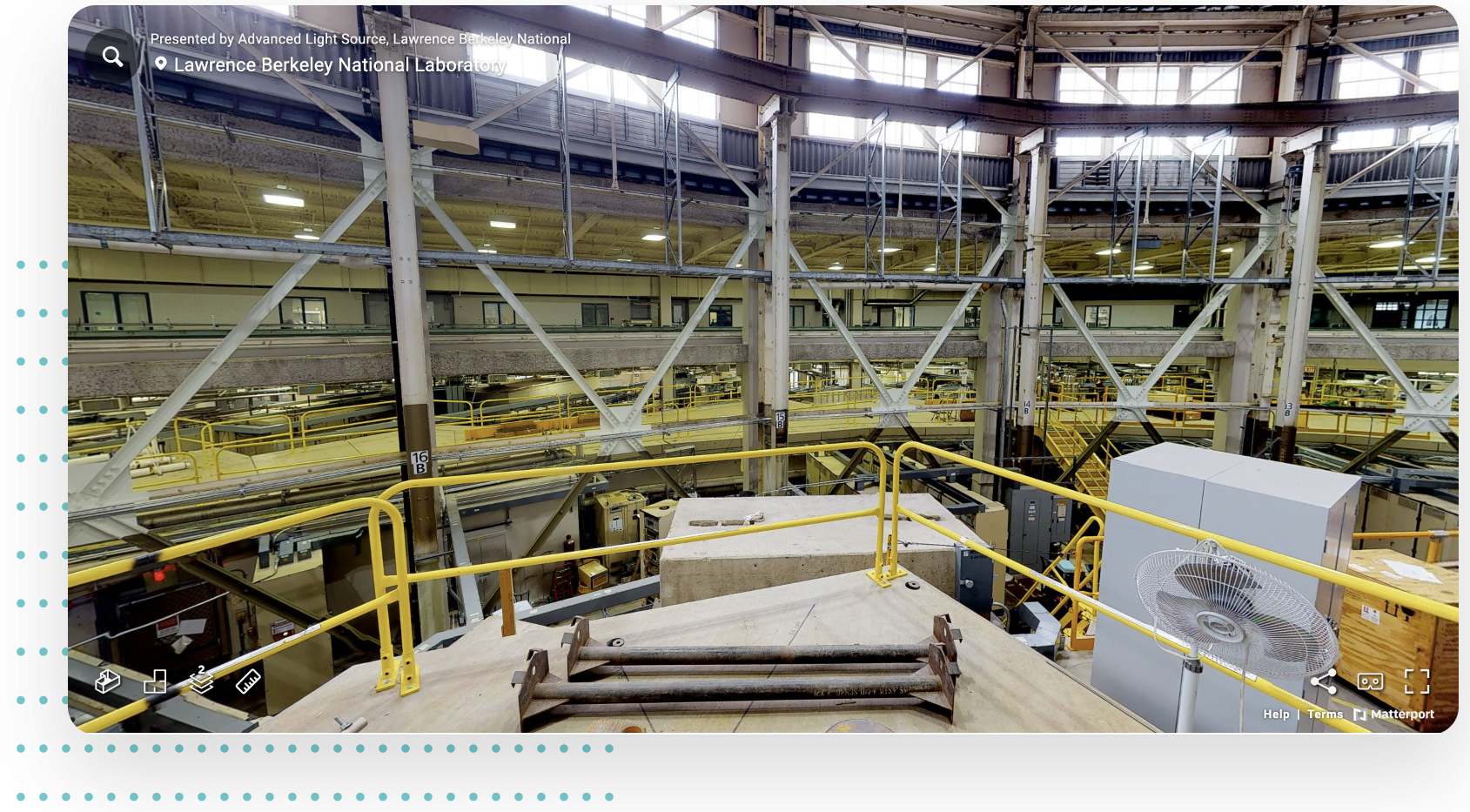

Zuant 3D in Action

Explore the 3D space below

How Zuant can Transform Manufacturing?

Invite new businesses to view your plant’s digital twin.

Open the door to new business relationships on a global scale by taking new customers on a guided tour of your plant's digital twin.

Demonstrate production volume through a visual tour, whilst providing real-time data examples using your Zuant dashboard.

Zuant 3D Transforms Manufacturing By:

Use your plant digital twin to perform tasks, collaborate with key decision makers, resolve issues, capture best practices, train your team, and allow process engineering to streamline workflows to improve overall efficiency.

Align manufacturing goals with your overall business objectives using your Matterport digital twin to monitor KPI success:

- Production volume

- Production costs

- On-time delivery

- Revenue per employee

Black Box for navigation (including emergency routes and congregation areas) with the ability to include training videos along the production line and detailed documentation through the Content Showroom.

Zuant x Matterports Features for Manufacturing

3D tours in manufacturing offer a virtual walk-through of production facilities, allowing stakeholders to gain an in-depth understanding of the layout, operations, and equipment used. This technology can improve collaboration, optimize production processes, and enhance the overall efficiency of manufacturing.

Features

-

Dollhouse and Google Street Views

-

Resolve - Escalate, assign and manage issues

-

Collaborate - Tap into collective knowledge

-

Capture - Best practices and solutions to problems

-

Perform Tasks - Ensure standard of work and identify deviations

-

Process Engineering - Save time, improve quality & streamline workflow

-

Virtual Training - Train employees using 3D invulnerable situations

-

Remote Service Management - Manage risk, hazard and incident documentation